ASTEPP project

The ASTEPP (Advanced Sensoring System for the Pulp & Paper industry) concept is developed by Cristini S.p.A. , one of the world’s leaders in the supply of special textiles (called paper machine clothing, working like conveyor belts) essential for in the paper production.

Cristini S.p.A. has a 100 years consolidated position in the paper production arena in Europe and North America.

The

ASTEPP project targets the paper industry and intends to introduce a new generation of advanced sensoring system to monitor and manage the different phases of the paper production process.

Paper production requires important amounts of water and energy (electric and thermal), therefore there is space for optimizations also on the latest generation paper machines.

In particular,

ASTEPP is focused on reducing water usage and increasing the energy efficiency in the paper production industry, thus bearing a substantial impact on processes which make a very intensive usage of resources.

The

ASTEPP sensors measurements applied to the different phases of the paper production, are among the most important value/parameters for efficient papermaking, allowing:

- Substantial energy savings

- Substantial water savings

- Substantial higher accuracy and precision rate than any currently available technologies, thus contributing to a reduction of material loss (paper)

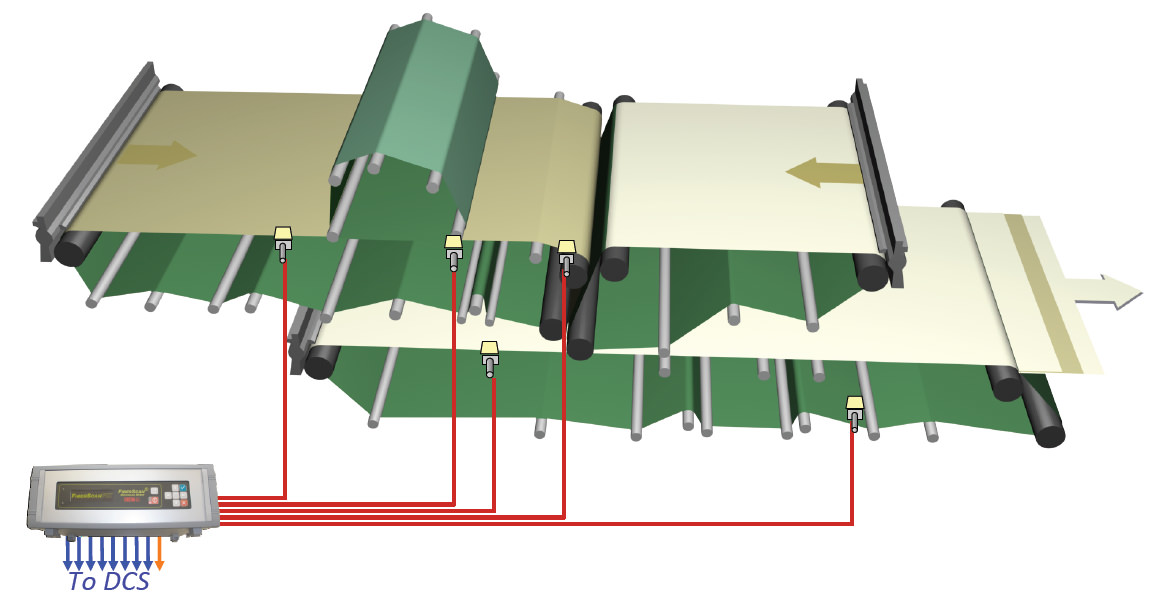

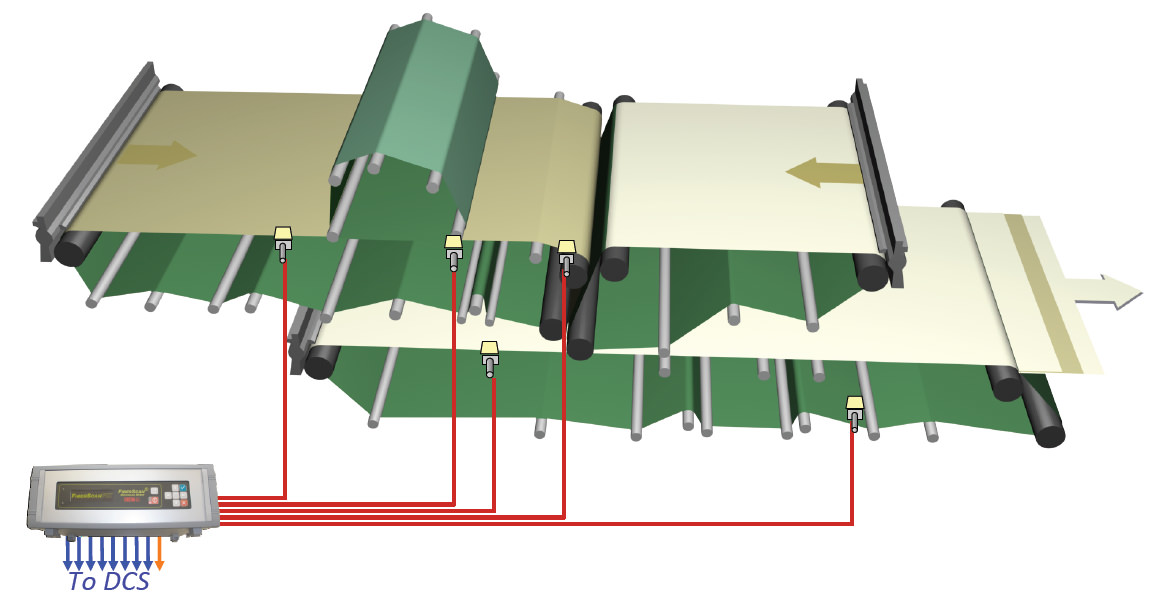

As described above, press fabrics and paper moisture control is therefore a fundamental part of the process.

It affects the product quality and at the same time, it has an influence on the production process costs. In particular, paper moisture control refers to specific aspects of the three phases illustrated.

The proposed technology ensures a more complete and resources efficient monitoring on those phases, allowing for each phase, on the following optimisations:

- Optimization/reduction of fiber refining;

- Optimization of the forming dewatering;

- Optimization/reduction of the water consumption;

- Optimization of the manufacturing process;

- Optimization/reduction of the press fabric conditioning;

- Optimization of the press fabrics change for wear. When a press fabric is worn out, it reduces the capacity to absorb water. The result is that paper enters the dryer section with a higher amount of water, requiring more steam to be dried. Therefore it is important monitor the fabric capacity to absorb water constantly.

- Optimization/reduction of the water consumption. Water is used to keep the press fabric clean

- Optimization/reduction of the steam consumption used to dry the paper. 1% increase in paper moisture entering the dryer section, is equal to 4% less steam consumption in the dryer section. This is consequent to the efficiency of the forming and press section. When paper moisture arises, immediate corrective actions can be taken in a fast and easy way.

- A continuous monitoring of the sheet moisture substitute the manual sampling of the sheet moisture, which present various risks factors (on the limited amount of paper machine where it is possible) and it is made only once a day. The moisture measurement trough sensors is more precise, eliminating the human influence, can be made in real time and the data downloaded to machine DCS.